- AML3D (AL3) has returned exceptional results from testing of its proprietary Wire Additive Manufactured (WAM) 3D printing technology

- WAM is a novel way of 3D printing high strength steel

- Independent testing by Intertek, revealed WAM demonstrated an ultimate tensile strength 30 per cent above the applicable global standard

- WAM’s possible use in a broad range of sectors comes with a bonus of not just added strength, but potentially reduced material usage

- AML3D also owns WAMSoft – metallurgical engineering and design software which fully automates 3D printing using advanced robotics technology

- AML3D is up 13.3 per cent at Friday’s close, with shares trading for 17 cents each

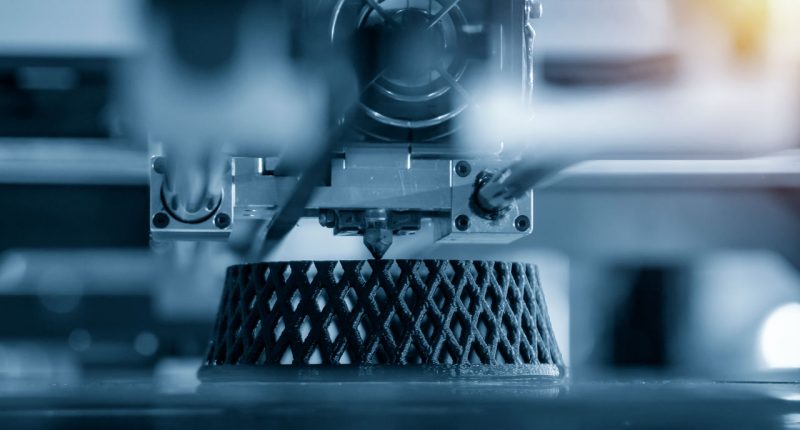

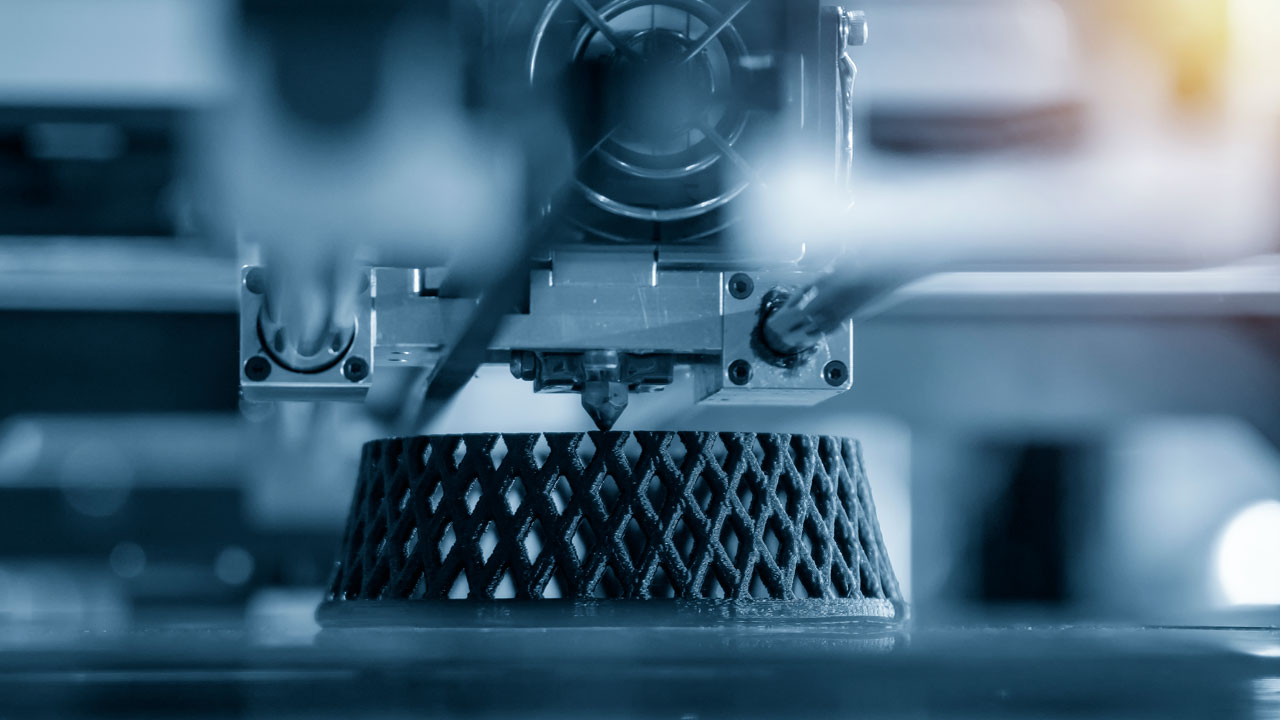

Advanced metals tech company AML3D (AL3) has returned exceptional results from testing of its proprietary Wire Additive Manufactured (WAM) 3D printing technology.

Wam, bam, thank you ma’am

WAM is a novel way of 3D printing high strength steel. Independent testing by National Association of Testing Authorities accredited group, Intertek, revealed WAM demonstrated an ultimate tensile strength 30 per cent above the applicable global standard.

WAM’s possible use in a broad range of sectors – including defence, resources, aerospace and automotive applications – comes with a bonus of not just added strength, but potentially reduced material usage. Customers could essentially choose if they want stronger like-for-like parts, or less heavy components of a similar strength.

Given the flexibility of 3D printing, WAM also offers the opportunity to easily manufacture steel parts 10 per cent stronger than those produced by conventional forging methods.

Double WAM-y

This new proof of the quality and efficacy of the WAM technology has two-fold implications.

Not only is the novel tech likely to substantially disrupt traditional manufacturing in defence, aerospace and other sectors, AML3D’s proprietary WAMSoft software enables the combination of metallurgical science and engineering design to fully automate the 3D printing process using advanced robotics technology.

This means AML3D has significant upside in design and engineering as well as simple manufacturing. Being the owner of such a vertically integrated technology and manufacturing platform puts the company at the cutting edge of metals tech.

AML3D is up 13.3 per cent at Friday’s close, with shares trading for 17 cents each.